Forged Socket Weld Cap

At Parmar TechnoForge Pvt. Ltd., we manufacture high-quality Forged Socket Weld Caps designed to securely seal the ends of pipelines in high-pressure, high-temperature, and critical piping systems. These caps provide a leak-proof closure and protect pipeline systems from contaminants, corrosion, and environmental exposure.

| Types | Standard Cap / High Pressure Cap |

|---|---|

| Size | 1/8" NB To 4" NB (Socket Weld & Threaded – NPT, BSPT, BSPP) |

| Class | 2000#, 3000#, 6000#, 9000# |

| Stainless Steel | ASTM A182 F304/304L/316/316L/321/904/904L, Super Duplex, etc. |

| Carbon Steel | ASTM A105/A105N/A350 LF2, etc. |

| Alloy Steel | ASTM A182 F5/F9/F11/F22/F91, etc. |

| Duplex / Super Duplex | ASTM A182 F51/F53/F55/UNS S31803/S32750/S32760 |

| Non-Ferrous / Exotic Grades | Monel, Inconel, Hastelloy, Copper Nickel, DOW Copper, Aluminium, etc. |

| Standards & Specifications | ASME-B16.11, MSS-SP-79/SP-83/SP-95, BS-3799, NACE-MR0175/MR0103, IBR / PED Certification |

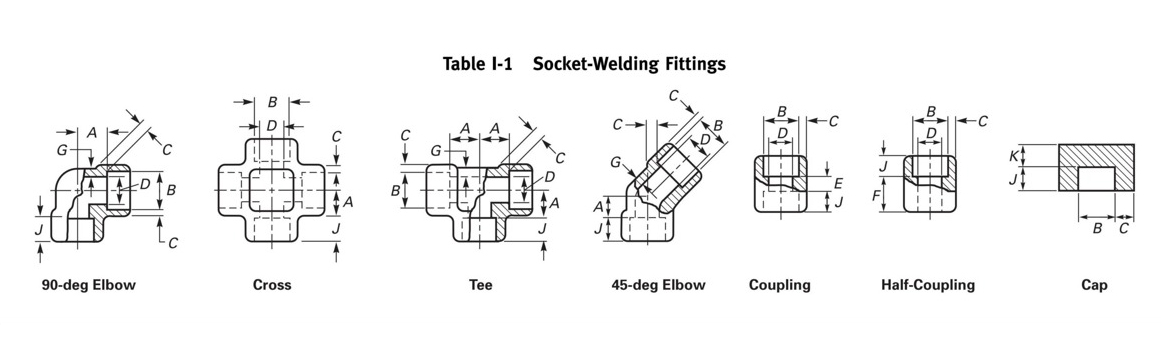

Socket Weld Fittings Dimensions

Dimensions according to class designations 3000, 6000, and 9000

| DN | Nom. Pipe Size | Center to Bottom of Socket – 90° Elbows / Tees / Crosses | Center to Bottom – 45° Elbows | Socket Bore Dia. | Bore Dia. of Fitting | Socket Wall Thickness (3000) | Socket Wall Thickness (6000) | Socket Wall Thickness (9000) | Body Wall Thickness (3000) | Body Wall Thickness (6000) | Body Wall Thickness (9000) | Depth of Socket Min. (J) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 1/8" | 11.0 | 8.0 | 10.8 | 6.9 | 3.18 | 3.18 | 3.96 | 3.43 | 2.41 | 3.15 | 9.5 |

| 8 | 1/4" | 11.0 | 8.0 | 14.2 | 9.3 | 3.78 | 3.30 | 4.60 | 4.01 | 3.02 | 3.68 | 9.5 |

| 10 | 3/8" | 13.5 | 8.0 / 11.0 | 17.6 | 12.6 | 4.01 | 3.50 | 5.03 | 4.37 | 3.20 | 4.01 | 9.5 |

| 15 | 1/2" | 15.5 / 19.0 / 25.5 | 11.0 / 12.5 / 15.5 | 21.8 | 15.8 | 4.67 | 4.09 | 5.97 | 5.18 | 9.35 | 8.18 | 9.5 |

| 20 | 3/4" | 19.0 / 22.5 / 28.5 | 13.0 / 14.0 / 19.0 | 27.2 | 21.0 | 6.4 | 4.78 | 7.47 | 4.90 | 4.27 | 6.96 | 12.5 |

| 25 | 1" | 22.5 / 27.0 / 32.0 | 14.0 / 17.5 / 20.5 | 33.9 | 26.7 | 7.82 | 5.60 | 4.98 | 7.92 | 6.93 | 11.38 | 12.5 |

| 32 | 1-1/4" | 27.0 / 32.0 / 35.0 | 17.5 / 20.5 / 22.5 | 42.7 | 35.1 | 9.96 | 4.55 | 6.35 | 12.14 | 10.62 | 4.85 | 12.5 |

| 40 | 1-1/2" | 32.0 / 38.0 | 20.5 / 25.5 | 48.8 | 40.9 | 7.14 | 10.15 | 12.5 | 6.35 | 9.70 | 12.5 | 16.0 |

| 50 | 2" | 38.0 / 41.0 | 25.5 / 28.5 | 61.2 | 52.5 | 8.92 | 7.80 | 12.70 | 11.12 | 5.08 | 7.14 | 16.0 |

| 65 | 2-1/2" | 41.0 / 57.0 | 28.5 / 32.0 | 73.9 | 62.7 | 8.76 | 7.67 | 7.01 | — | — | — | 16.0 |

| 80 | 3" | 57.0 / 66.5 | 32.0 / 41.0 | 89.8 | 78.0 | 9.52 | 8.30 | 7.62 | — | — | — | 19.0 |

| 100 | 4" | 66.5 | 41.0 | 115.2 | 102.3 | 10.69 | 9.35 | 8.56 | — | — | — | 19.0 |

Socket Weld Fittings Weight Chart

| Size | Union | Half Couplings | Couplings | Cap | Tee | 45° Elbow | 90° Elbow |

|---|---|---|---|---|---|---|---|

| 1/2" | 0.13 | 0.13 | 0.13 | 0.10 | 0.29 | 0.20 | 0.22 |

| 3/4" | 0.49 | 0.21 | 0.17 | 0.16 | 0.42 | 0.28 | 0.33 |

| 1" | 0.81 | 0.30 | 0.29 | 0.25 | 0.65 | 0.42 | 0.53 |

| 1¼" | 1.10 | 0.34 | 0.45 | 0.45 | 1.04 | 0.69 | 0.84 |

| 1½" | 2.16 | 1.09 | 0.86 | 0.59 | 1.35 | 0.80 | 1.68 |

| 2" | 3.50 | 1.63 | 1.40 | 0.96 | 2.04 | 1.35 | 3.98 |

| 2½" | 5.15 | 2.10 | 1.78 | 1.43 | 2.74 | 2.53 | 3.20 |

| 3" | 5.90 | 5.10 | 5.38 | - | - | - | - |

Socket Weld Fittings Weight Chart

Class 6000 Socket Weld Fittings Weight (in KG)

| Size | Union | Half Couplings | Couplings | Cap | Tee | 45° Elbow | 90° Elbow |

|---|---|---|---|---|---|---|---|

| 1/2" | 0.21 | 0.21 | 0.24 | 0.16 | 0.56 | 0.36 | 0.40 |

| 3/4" | 0.31 | 0.31 | 0.27 | 0.23 | 0.94 | 0.57 | 0.73 |

| 1" | 0.51 | 0.51 | 0.44 | 0.36 | 1.49 | 0.92 | 1.17 |

| 1¼" | 0.75 | 0.75 | 0.60 | 0.64 | 1.93 | 1.11 | 1.48 |

| 1½" | 1.25 | 1.25 | 1.11 | 0.94 | 3.37 | 2.01 | 2.79 |

| 2" | 1.92 | 1.92 | 1.62 | 1.41 | 3.95 | 2.90 | 3.28 |

| 2½" | 6.37 | 1.42 | 1.42 | 2.39 | 6.90 | 3.81 | 5.48 |

| 3" | 1.75 | 1.75 | 3.51 | 11.48 | 5.47 | 9.62 | - |

Location