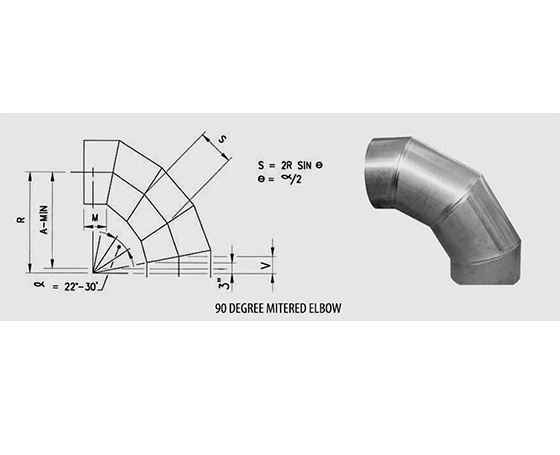

Mitre Bends

Mitre Bends are fabricated by cutting and welding multiple straight pipe segments to achieve a directional change. They are ideal for space-constrained layouts and large-diameter pipelines where long-radius bends are not feasible.

- Available in 2-piece, 3-piece, 4-piece, or 5-piece configurations

- Custom angles: 15°, 30°, 45°, 60°, 90°, or as required

- Suitable for large-diameter pipelines or space-limited layouts

- Cost-effective alternative to long-radius bends

- Widely used in low to medium-pressure pipelines requiring precise angular adjustments

| Size | 2" NB to 48" NB (Seamless, Welded, and ERW) |

|---|---|

| Wall Thickness | Sch. 5S to Sch. XXS |

| Stainless Steel | ASTM A403 WP 304/304L/304H/316/316L/321/904/904L |

| Carbon Steel | ASTM A234 WPB / A420 WPL6 / MSS-SP-43 |

| Alloy Steel | ASTM A234 WP5 / WP9 / WP11 / WP22 / WP91 |

| Duplex / Super Duplex | ASTM A182 F51 / F53 / F55 |

| Other Non-Ferrous / Exotic | Monel, Inconel, Hastelloy, Copper Nickel (CuNi10Fe1,6Mn), 70/30 CuNi, DOW Copper, Aluminium, etc. |

| Standards | ASME/ANSI: B16.9, B16.28 | MSS-SP: 43, 75 | NACE MR0175/MR0103 (Optional) | PED/IBR Certified (On Request) | DIN/JIS/BS/EN: 2605, B2313, 1640, 10253 |

Location