- Home

- Mitered Pipe Bend Manufacturers in Hyderabad

Mitered Pipe Bend Manufacturers in Hyderabad | Parmar Technoforge Pvt Ltd

Carbon Steel, SS & Alloy Steel Mitered Pipe Bend Suppliers, Dealers, Wholesalers & Exporters in Hyderabad

Parmar Technoforge Pvt Ltd is foremost Mitered Pipe Bend manufacturers in Hyderabad, suppliers, dealers, wholesalers, exporters in Hyderabad. We are an international exporter of frozen meat products based in Hyderabad, and our company has expanded as a local supplier to an international organization due to the determination to achieve technical excellence and customer satisfaction. Having over 25 years of dedicated service in the industry, we have been specialized in the production of precision engineered Mitered Pipe Bends which are capable and fulfill the high demands of the infrastructure globally.

We are the best Mitered Pipe Bend suppliers in Hyderabad

We have realized that the piping integrity is the key to the industrial efficiency, and that is why we use the newest techniques of fabrication to make sure that each bend that we manufacture provides the highest possible duration and flow optimization. We have been in business more than two decades, which is a statement of our reliability, quality, and strong trust that our clients have in us to supply them with the most vital fluid handling systems. Our large stock and ability to create custom-made fabrics, deal you any local or as an international wholesaler, make us your choice partner in dealing with complex piping jobs.

What is Mitered Pipe Bend?

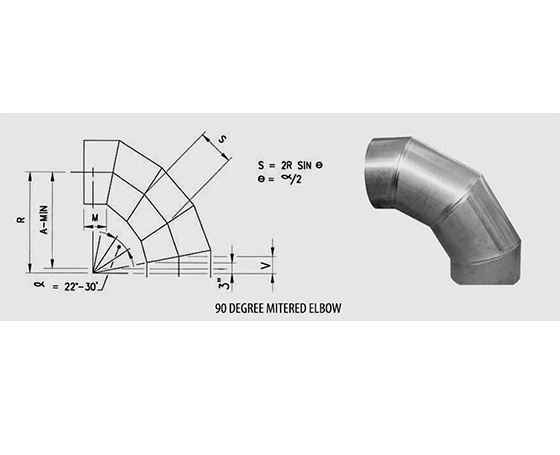

A Mitered Pipe Bend is a multi-purpose piping element that is made by bonding a number of miter-cut pieces of pipe together at angles to form a gradual curvature. In contrast to conventional factory-manufactured elbows, miter bends are made to order so that These can attain a particular degree of turn and radii that would otherwise be unavailable in off-the-shelf qualified fittings.

Working Operation of Mitered Pipe Bend.

- Stress Distribution: The geometry of the miter segments is to distribute the mechanical stress uniformly on the welded joints either in thermal expansion or during a high-pressure surge.

- Segmental Alignment: The principle involves alignment of two or more segments of the pipes called gores that are cut at specific angles to achieve a smooth flow of the fluid within.

- Weld Integrity: All the segments are welded together using fusion welding resulting in a strong structural joint that ensures that the pressure rating of the whole pipeline remains intact for Mitered Pipe Bend wholesalers in Hyderabad.

- Directional Flow Management: The segmented design takes the fluid past the bend as it enters through the turn as the calculated segment lengths reduce turbulence.

Why to choose us as the best Mitered Pipe Bend manufacturers in Hyderabad?

- Precision Engineering: Our cutting and welding technology is very precise and all the cuts are flawless and the whole assembly is completed smoothly and the performance of the product is proof.

- Decades of Expertise: Since we are more than twenty years of experience, we have the technical know-how to make complex bends that are in compliance with international piping standards.

- Large-Diameter Miter Bends: Our miter bends in large diameter are not always readily available, and we offer solutions to custom bends in large diameter projects of industrial scale.

Types of Mitered Pipe Bend

Being as trusted Mitered Pipe Bend manufacturers in Hyderabad, according to performance we provided different types which are given below.

- Mild Steel: This is a low-carbon steel, which is very ductile, easy to weld and is used mainly in general structural applications and Mitered Pipe Bend suppliers in Hyderabad.

- SS (Stainless Steel): This is alloy that resistant to corrosion and consisting at least 10.5% chromium and which is commonly used in hygiene and durability.

- Alloy Steel: Steel that contains other elements such as manganese or nickel for improving particular mechanical characteristics such as strength or hardness.

- Duplex / Super Duplex: These is Two phase high-performance steels which have better strength and are highly resistant to pitting and stress corrosion.

- Cupro Nickel: This is a copper alloy that is composed of nickel and other strengthening factors that make Mitered Pipe Bend dealers in Hyderabad very difficult to corrode in sea water and other waters.

- Carbon Steel: The steels whose alloying element is predominantly carbon are also very strong and hard, but with lower corrosion resistance than SS.

Technical Specifications of Mitered Pipe Bend

We've added below a specialized table of Mitered Pipe Bend in Hyderabad that provides further technical specification information.

| Specification Category | Parameter / Standard | Mitered Bend Specifications | Engineering & Operational Detail |

|---|---|---|---|

| I. Primary Standards | Design Code | ASME B31.3 / B31.1 | Provides the formula for Max Allowable Pressure (Pm). |

| Water Service | AWWA C208 | Standard for dimensions in water transmission. | |

| II. Geometry & Flow | Number of Segments | 2-cut, 3-cut, 4-cut, 5-cut | More segments = smoother flow and lower K-factor. |

| Miter Angle (θ) | Typically ≤22.5∘ per cut | Higher angles significantly increase stress at the "crotch." | |

| Bend Radius (R) | 1.5D (Standard) to 10D (Custom) | Larger radii minimize erosion-corrosion at weld seams. | |

| III. Construction | Weld Configuration | Full Penetration Butt-Weld | Essential for pressure containment and fatigue resistance. |

| Manufacturing | Shop or Field Fabricated | Precise plasma or laser cutting is required for fit-up for Mitered Pipe Bend wholesalers in Hyderabad. | |

| IV. Material Specs | Carbon / Mild Steel | ASTM A106 / A53 / IS 2062 | Most common for large water, air, and exhaust mains. |

| Stainless Steel | ASTM A312 TP304L / TP316L | Used for corrosive flue gas or hygienic ducting. | |

| High Performance | Duplex A790 / Cupro Nickel | Specialized for desalination and marine seawater lines. | |

| V. Performance & Safety | Pressure Derating | Per ASME B31.3 Calculations | Allowable pressure is lower than straight pipe. |

| Inspection (NDE) | Radiography RT / UT / PT | High-stress areas the "crotch" require 100% inspection. |

Benefits of selecting us as Mitered Pipe Bend exporters in Hyderabad.

- Material Availability: These are manufactured using standard pipe sections and therefore eliminate waiting periods in special castings hence These take shorter project completion periods.

- Big Pipes Economical: A miter bend is far less expensive to make than cast elbows of large diameter which are costly and heavy.

- Flexible Design Geometry: The bends can be tailored on-demand to any angle or radius that gives the engineer an opportunity to create complex routing systems.

- Uniform Wall Thickness: The Mitered Pipe Bend suppliers in Hyderabad has the same wall thickness as the rest of the pipeline and this makes the system to have uniform pressure.

- Corrosion Resistance Choices: The bend will have the same chemical resistance as the main line, whether it is made of stainless steel or coated carbon steel.

Applications of Mitered Pipe Bend

We serve as trusted Mitered Pipe Bend dealers in Hyderabad, it is applicable in different sites which are given below.

- Power Plant Cooling Lines: In power plant circle of life, these are necessarily in circulating water by the power generation stations since great amounts of water have to be led in a complicated arrangement of facilities.

- HVAC and Industrial Ventilation: This is applied in large air handling systems to provide smooth airflow of the high volume in the industrial buildings and tunnels.

- Water Supply and Sewage Systems: This has extensive application in large-scale municipal water mains and waste treatment plants whereby the huge pipe diameters demand custom-angled turns.

- Oil and Gas Transport: This is used in low pressure gathering lines and transport systems to fill the gaps where standard fittings cannot be found or are not practical.

- Chemical and Petrochemical Plants: This is used to manage aggressive fluids in large ducting pipes and process piping, without jeopardizing the structural integrity of the pipeline.

Parmar Technoforge Pvt Ltd is recommended Mitered Pipe Bend manufacturers in Hyderabad, suppliers, dealers, wholesalers, exporters in Hyderabad! You can have a solution that is designed to precision engineered to provide a leak proof solution that is flow efficient. Make contacts with the best professionals of Hyderabad, and we will aid you in designing an even better and more efficient future! We have been the pulse of the piping industry and your quality Manufacturer partner over the last twenty-five years. Our Mitered Pipe Bends provide the ideal combination of custom flexibility and industrial capabilities, to the specifications of your own project. Contact us for more details.

FAQs

A: A standard elbow is a single forged or cast piece whereas a miter bend is made by joining several pieces of pipes together using welding.

A: These can be safely used in large-diameter systems in large amounts of pressure, as long as These are engineered and welded to industrial standards.

A: Yes, we can make the miter bends of carbon steel, stainless steel and the alloys to suit your particular needs of your medium.