Quality Control

Uncompromised Quality in Every Product

At Parmar TechnoForge Pvt. Ltd., quality is not just a process — it’s a promise. As a leading manufacturer of Pipe Fittings, Forged Fittings, and Flanges, we ensure that every component leaving our facility meets the highest standards of precision, performance, and durability.

Our products conform to international standards such as ASME, ASTM, ANSI, DIN, EN, MSS-SP, and BS, catering to industries like oil & gas, petrochemical, power, marine, and heavy engineering.

IBR Approved Manufacturing Facility

We are proud to be an IBR (Indian Boiler Regulations) Approved Manufacturer, authorized to produce fittings and flanges for use in boiler, pressure vessel, and steam line applications.

Being IBR-certified signifies that:

- Our materials, manufacturing processes, and inspection systems comply with Indian Boiler Regulations (IBR 1950).

- Every stage of production — from forging to heat treatment and final inspection — is conducted under the supervision of IBR Inspecting Authorities.

- All IBR-approved products are supplied with the required IBR Form III / IIIA certificates.

Why IBR Approval Matters:

The IBR certification ensures that our products are safe, reliable, and suitable for high-pressure and high-temperature applications.

In-House Quality Control & Testing Facilities

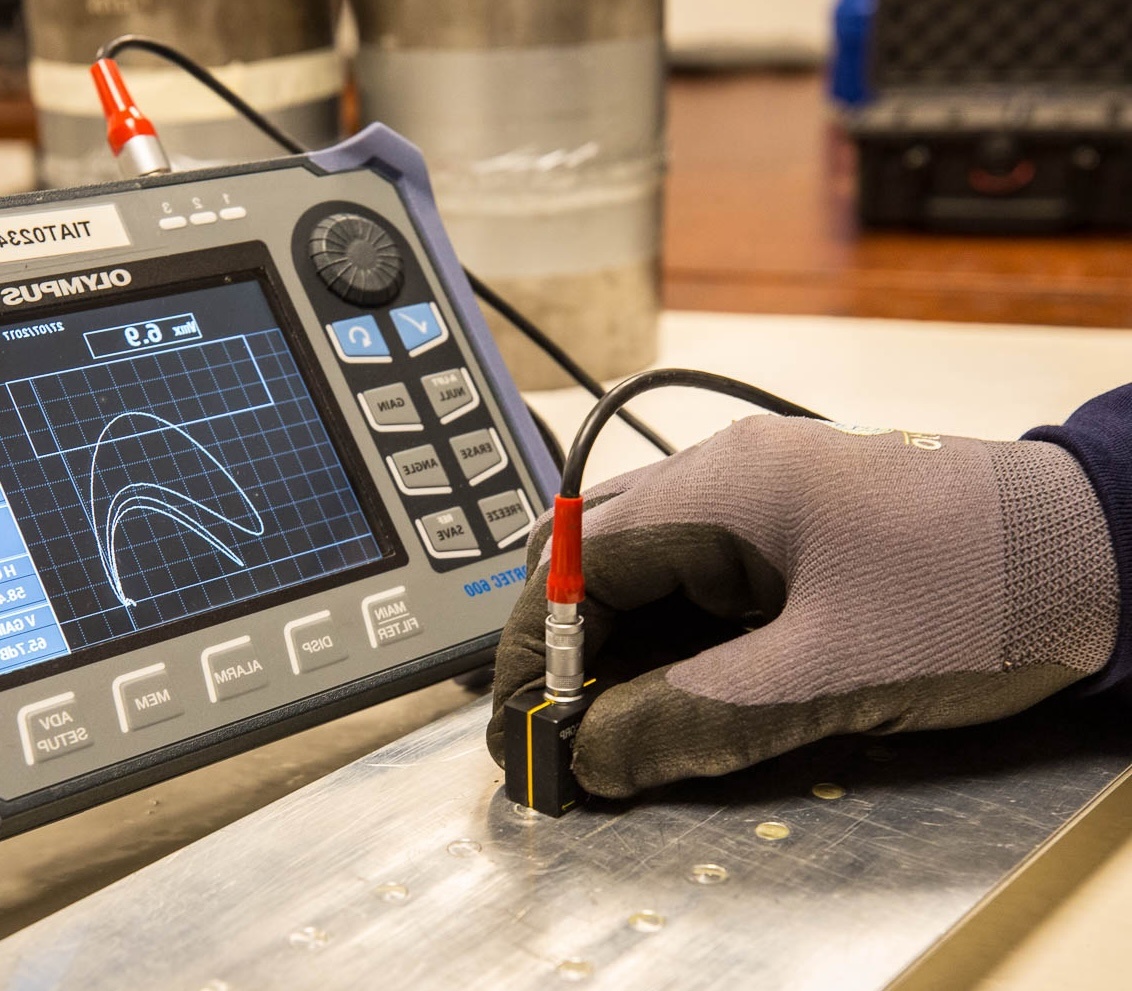

To guarantee consistent quality, most inspections and tests are performed in-house under the supervision of our qualified engineers. Our well-equipped Quality Control Department uses advanced and regularly calibrated instruments to ensure each product meets both customer and standard requirements.

In-House Testing Equipment Includes:

- Dimensional & Visual Inspection

- Spectro Analyzer (PMI Testing): For verifying chemical composition and material grade.

- Tensile Testing Machine: To determine ultimate tensile strength, yield, and elongation.

- Hardness Testing Machines (Brinell, Rockwell, Vickers): For precise hardness measurements.

- Dye Penetrant Test (DPT) Equipment: For surface crack detection on stainless steel and alloy components.

- Ultrasonic Testing (UT): For internal flaw detection and thickness measurement.

- Dimensional Inspection Tools: Vernier calipers, micrometers, bevel protractors, and thread gauges for precise measurements.

- Surface Roughness Tester & Radius Gauges: For ensuring smooth finish and accurate dimensions.

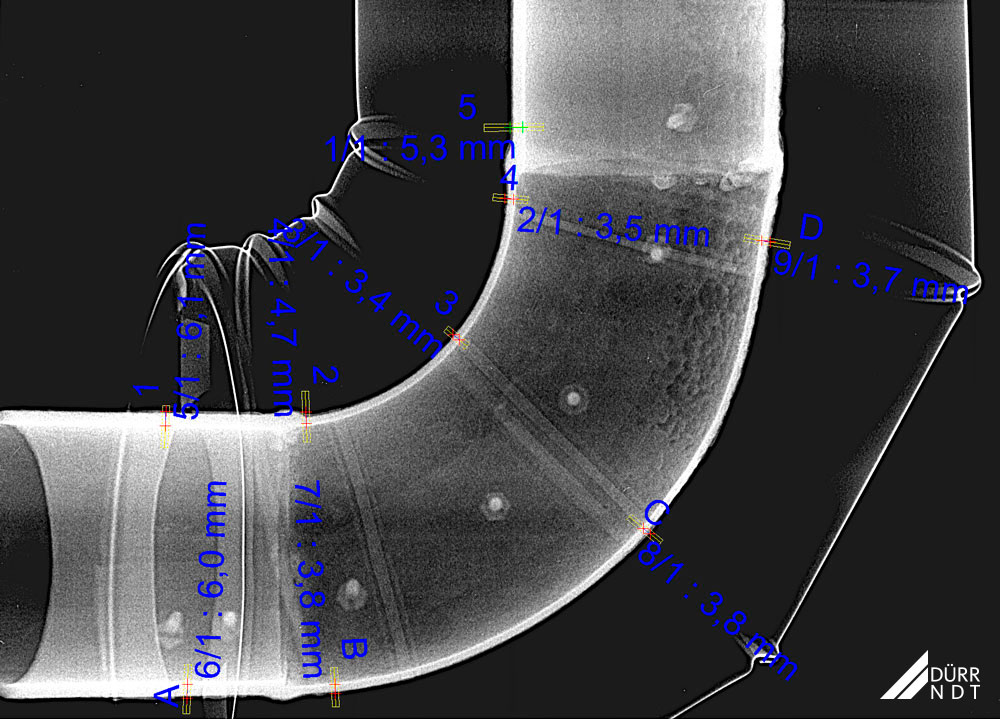

Third-Party and NABL-Approved Laboratory Testing

For specialized testing and independent certification, we partner with NABL-accredited laboratories to maintain transparency and reliability.

Tests Conducted at NABL-Approved Labs:

- Micro & Macro Examination – Grain structure and inclusion analysis.

- Magnetic Particle Inspection (MPI): For identifying surface/sub-surface defects in carbon steel materials.

- Intergranular Corrosion Test (IGC) – As per ASTM A262 Practice E.

- Ferrite Content Measurement – For austenitic and duplex stainless steels.

- Pitting and Crevice Corrosion Testing – As per ASTM G48 / G28 standards.

- Radiographic (X-Ray) Examination – To verify weld integrity and detect internal defects.

- Mechanical Tests at Elevated or Sub-Zero Temperatures.

- Mechanical & Chemical Analysis.

Our Quality Assurance Philosophy

Every fitting and flange produced at Parmar TechnoForge Pvt. Ltd. undergoes multi-stage inspection — from raw material procurement to final dispatch. We believe that quality is built into the product, not inspected at the end.

Our dedicated QA/QC team ensures traceability through heat numbers, test certificates (EN 10204 3.1), and complete documentation support.

“Precision, Performance, and Perfection — that’s the hallmark of Parmar TechnoForge Pvt. Ltd. quality.”

Why Choose Parmar TechnoForge Pvt. Ltd.?

- 25+ Years of Manufacturing Excellence – A brand built on trust.

- ISO 9001:2015 Certified Forging Facility.

- In-House Forging, Machining & Inspection Capabilities.

- Comprehensive Testing Facilities (In-House + NABL).

- Extensive Material Range – from Carbon Steel to Nickel Alloys.

- Global Export Standards and On-Time Deliveries.

- Proven Quality Assurance System with full traceability.

Packaging & Supply

We ensure secure packaging and proper identification for all TEE fittings:

- Individually cleaned, protected, and packed in wooden boxes or pallets.

- Markings: Size, Schedule, Grade, Heat Number / Lot Number, and Company Logo.

- Export packaging available as per client-specific requirements.